Ciacci, Luca; Eckelman, Matthew J.; Passarini, Fabrizio*; Chen, Wei-Qiang; Vassura, Ivano; Morselli, Luciano

Journal of Cleaner Production 2014 84, 540-549. DOI: 10.1016/j.jclepro.2014.03.062

Abstract

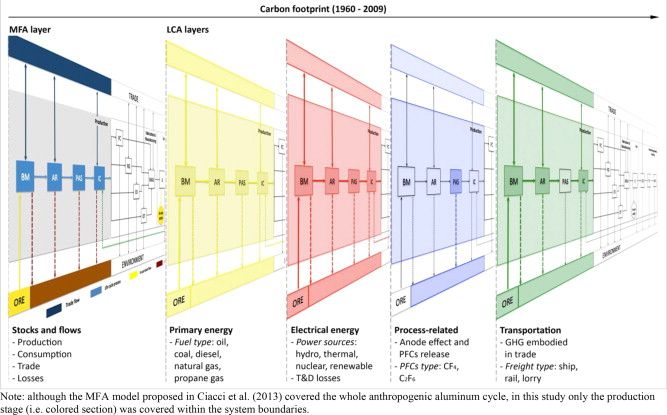

Standard material flow analysis (MFA) and life cycle assessment (LCA) models were combined to analyze the historical evolution of greenhouse gas emissions of Italian aluminum over the years 1960–2009 with the aim of providing key features to Italy for prioritizing future industrial and environmental policies. Annual greenhouse gas emissions were calculated for primary and electrical energy, process-related and transportation. Cradle-to-gate emission factors were defined per ton of aluminum produced and used to quantify the cumulative carbon footprint. Consolidation of the model was carried out at domestic and foreign levels for aluminum production in order to analyze the shift in emissions transfers between the location of production and that of use. Overall, average percent contributions from the main CO2e-related process reflect the trend of the global aluminum industry in upgrading to standardized production processes worldwide. Cumulative carbon footprint of Italian aluminum was estimated in about 375 MtCO2e, of which only 188 MtCO2e is from domestic production. Because Italy is a net importer of aluminum, greenhouse gas emissions from the final use of aluminum have increased the impact of domestic production by 140% in the last decade. A potential carbon emissions savings of ∼160 MtCO2e could result if the current anthropogenic aluminum in-use stock will be quantitatively recycled. The study showed potentials for combining MFA and LCA to improve completeness when approaching environmental issues. The outcomes revealed chances for decreasing the contribution to climate change from the aluminum industry and allowed the setting of country indicators usable in future national LCA studies.

Scheme for combining MFA and LCA layers applied in the study.